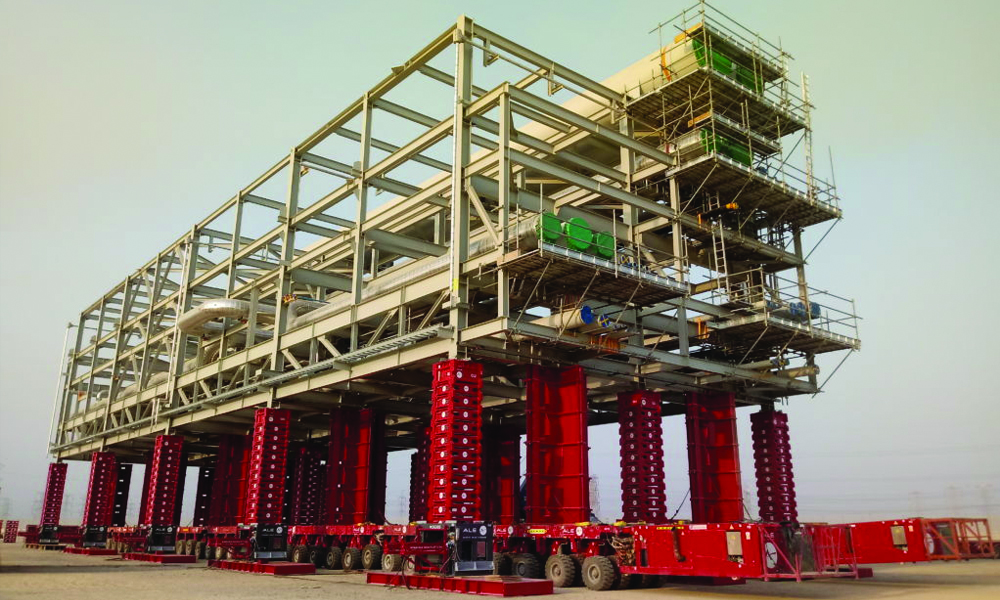

ALE’s Mega Jack 300 has performed its 100th jack-up on the Al Zour oil refinery project in Kuwait.

The innovative jacking system is currently working on the oil & gas complex, expected to become one of the largest refineries in the world. ALE is providing the full onshore heavy-lifting solution for the Fluor Daweoo and Hyundai JV module strategy, performing the jack-up, transportation and installation of 188 modules.

Named for its 300t capacity per tower, the Mega Jack 300 was launched last year and is the latest edition to ALE’s Mega Jack fleet. ALE calls it a cost-effective jacking solution for any type of site condition. Its components are easy to handle, being considerably more compact and lightweight than previous models, so reconfigurations can be made quickly on-site.

The Al-Zour refinery is the Mega Jack 300’s debut operation. It commenced work on the project in 2018 and previous lifts have included the longest and highest module ever jacked up and installed in Kuwait. As the modules all vary in weight and dimensions, the system’s flexibility has been vital for the project. Its balance and low starting height have enabled it to pick up loads directly from SPMTs for this project, while the accuracy of the control systems has ensured modules can be manoeuvred safely.

Sarkis Juvelekian, project site manager, said: “The Mega Jack 300 is an ideal lifting solution for projects like this that need flexibility and speed from on-site equipment. The system is performing well, even in conditions with high utilisation in environments as harsh as Kuwait’s extreme heat and dust.”

The Al-Zour complex is divided into three projects and includes a refinery, liquefied natural gas processing facilities and a petrochemicals complex. Project completion is planned for 2020 and it is expected to deliver 615,000 barrels per day.