Volvo Construction Equipment (Volvo CE) has developed a new Common Pressure Rail Hybrid system for hydraulic efficiency in excavators, which improves performance while reducing CO2 emissions.

A statement from the Swedish equipment giant said a Volvo CE team from Sweden and South Korea has worked closely with Finnish company Norrhydro in the research project, leveraging an idea initially born out of academic collaborations.

“In line with Volvo Group’s net zero value ambitions by 2040, the innovation has matured into a real-world solution with ongoing customer trials in the field and it is expected to accelerate the introduction of e-mobility across Volvo CE’s larger excavator platform. The company anticipates the new technology to be available in the excavator market in a near future,” added the statement.

Lars Stenqvist, CTO, Volvo Group, explained: “This innovation enables Volvo CE to offer its customers a truly unique electro-hydraulic solution, pushing fuel efficiency to new levels. It’s demonstrating the passion of our engineers to bring forward customer-oriented solutions and systems that will drive the transformation towards net-zero emissions operations. Also, it’s again an example of our strength working in partnerships and achieving amazing results.”

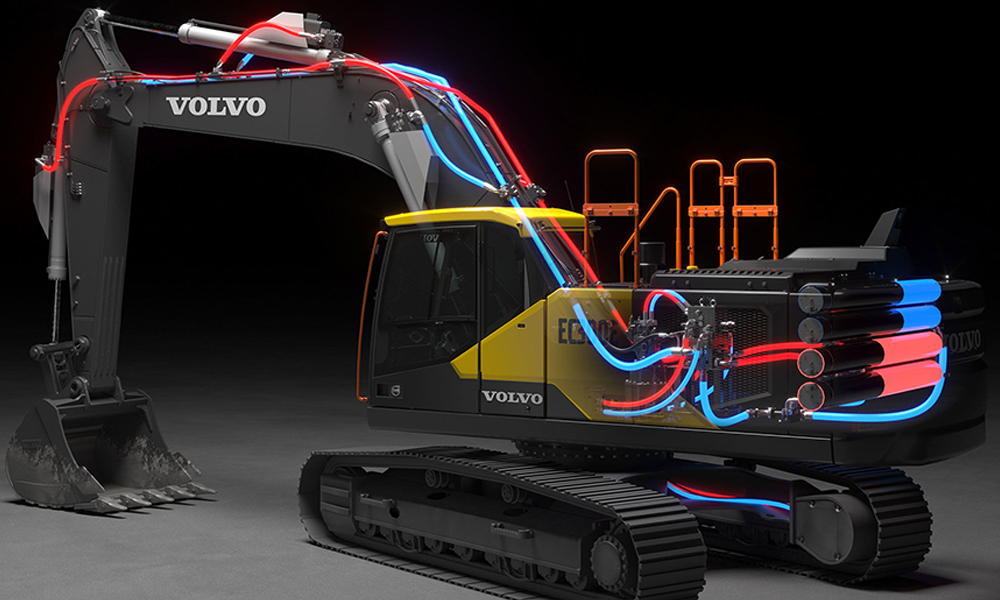

The innovation enables new ways to reduce energy losses in hydraulics. In the new system architecture all the machine’s work functions are connected to a hydraulic energy storage via a common pressure rail, comprised by two or more pressure lines. The energy storage, which consists of hydraulic accumulators, enables energy-efficient recovery of kinetic energy and peak power supply. For cylinder-driven functions, so-called “smart actuators” are used to achieve energy-efficient conversion from hydraulic power to a variable force and speed.

The system also allows energy recovery and performance increase of the machine’s rotating loads, such as the swing function through the introduction of variable hydraulic machines. Thanks to greatly reduced energy losses and the power contribution from hydraulic accumulators, a smaller power source can be used and the need for cooling is reduced. With a higher available power, cycle times can be shortened, for example when loading a truck, which contributes to both efficiency increases and cost benefits for the customer.

The ground-breaking electro-hydraulic system has been awarded the Volvo Technology Award, which is a mark of recognition for outstanding technical advances that contribute to the enhancement of the Volvo Group’s high-tech competitiveness and technological expertise. Previous recipients have included world-famous innovations such as the Duo-Prop marine drive, the City Filter used to purify trucks and bus exhausts, Volvo’s side airbags (SIPS) and the Electric Site emission free quarry research project.

Kim Heybroek, Volvo CE emerging technologies research engineer and a member of the winning team, said: “We are really proud of this recognition, which we share with our collaboration partners. The potential in the innovation has been a strong driver for us in the project, making it an exciting journey to be part of, as we see the significant benefits it will offer for our customers and help build the world we want to live in.”

The winners of the Volvo Technology Award 2021 are: Kim Heybroek, Sangki Bae, Junwoo Kim, Byeongmo Ko, Donghun Oh, Wonkil Choe, Wontaek Oh and Namgyu Kim.