Weir Group will integrate vertical stirred grinding mills technology into the business as part of a new alliance with Swiss Tower Mills Minerals AG (STM), the company has announced.

Designed to improve throughput and energy efficiency, STM’s vertical stirred grinding mills for coarse grinding applications offers a low energy alternative to traditional high energy consuming tumbling mills. According to Weir, it will be integrated into a single flow sheet, delivering significant reductions in energy use, driving down costs and carbon emissions.

The technology is already well-known for energy efficient comminution in the mining market with more than 80 units currently operating in the hard rock mineral processing industry globally. It is used within the comminution segment of the minerals processing circuit as part of a series of crushing and grinding processes that create the fine particles from which minerals can be extracted through floatation.

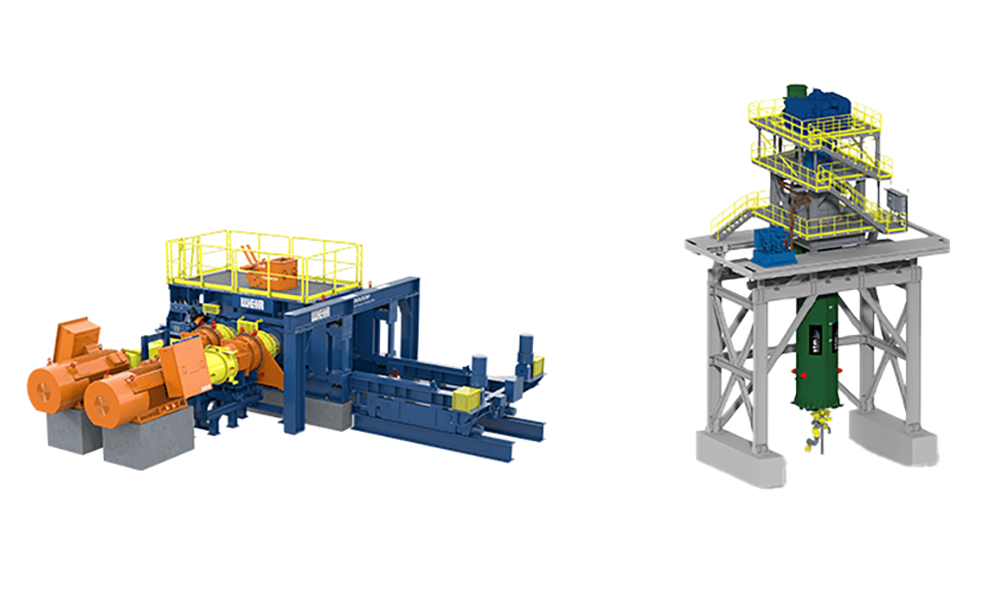

Comminution is one of the most energy intensive parts of the mine, accounting for 25% of the final energy consumption of an average mine site. The vertical stirred grinding mills further complement Weir’s existing comminution technologies, such as Enduron® HPGRs which the company says are driving down energy consumption by around 40% for its customers.

In a statement announcing the new alliance, Ricardo Garib, Weir Minerals Divisional President said. “Weir and STM share the same vision of enabling primary resource providers to produce resources in the most sustainable manner. This is a perfect match of best-in-class technology providers.”

He added: Integrating STM mills with Weir’s comminution products, which includes Enduron® high pressure grinding rolls (HPGRs) and Enduron® screens, will improve throughput and help bring substantial reductions in carbon emissions. This is a real win-win.”