Digitalisation holds enormous potential to help quarries boost their competitiveness – and a tailored, partnership-led approach is key to unlocking the benefits in a practical and affordable way, says Andrey Komov, Head of Productivity for Region International at Volvo Construction Equipment.

In production applications, such as quarries, that involve repetitive jobs and moving large amounts of materials, failing to adopt a digital transformation strategy can have severe repercussions. Even small efficiency gains per tonne moved can add up to significant savings over time, improving competitiveness and the bottom line, but these opportunities can be difficult to detect with traditional methods.

And that’s not the only benefit. Real-time monitoring of machines and operator behaviour enables quarry managers to spot deviations that could lead to downtime and proactively implement safety measures to prevent accidents. Meanwhile, reduced administration and paperwork empowers workers to focus on more critical tasks, leading to increased productivity, and makes the quarry a more appealing workplace, helping to attract skilled workers in a competitive labour market.

Digitalisation is not a cure-all solution, however, rather a tool that must be used in the right way and for the right purposes. Every customer has unique challenges and objectives, and we encourage them not to face them alone. Instead, let’s work together in partnership.

Insight, Analyse, Improve and Sustain

We listen to customers carefully and take them through a four-step process – Insight, Analyse, Improve and Sustain – to develop a tailored programme that will help achieve sustainable improvements to their operations. This programme will involve various services according to the specific results customers are looking for, and in cases where we do not have a ready-made solution, we see it as an opportunity to brainstorm and develop a custom approach.

‘Plug and play’ with affordable subscriptions

That does not mean it has to be expensive, however. There is a misconception that digitalisation is only affordable for those who can put a six or seven-digit budget behind it, but we are challenging and changing this paradigm. The fact that our solutions are subscription based allows customers to start with any budget without the need for huge upfront investments. Indeed, we would recommend that customers start small and make adjustments on the go, rather than trying to make the perfect plan for digitalisation and never taking action.

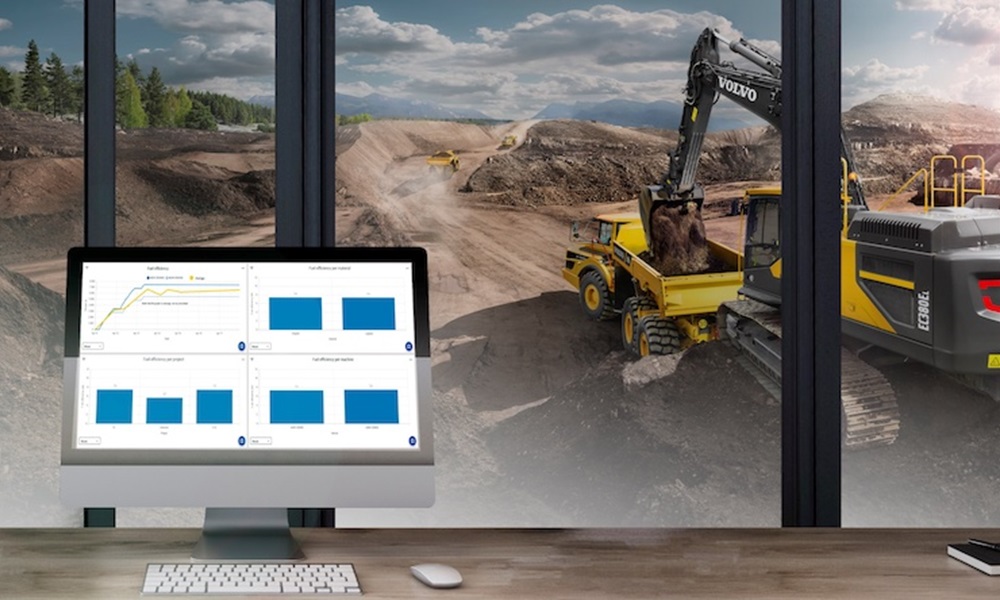

To make it even easier for quarry operators, we have developed solutions that are brand agnostic. In other words, they allow customers to ‘plug and play’ with any machine, but naturally with wider functionality when integrated into a Volvo machine via our Co-Pilot platform. We are constantly learning with our customers, and our list of solutions will continue to grow over time.

Success stories with digital solutions

So far, the positive feedback has been a great source of motivation for us. One customer, who adopted our Performance Indicator and Connected Map technologies, reported saving four hours per week on reduced administration time. This translates to 208 hours per year or 26 working days of management time.

Meanwhile, several customers who have implemented our Connected Map technology have reported increased operator awareness of vehicle traffic flow. Operators can now slow down when they see a line forming to be loaded by an excavator, instead of rushing to the spot and waiting. This, combined with speed zone implementation, has led to a positive effect on fuel consumption. Obviously, the best results can be achieved by sufficient on-site connectivity.

Furthermore, by conducting site optimisation work, we can analyse cycle data from a customer’s operations and help them identify improvement potential. In one instance, we noted a long wait time for truck loading and dumping. Further investigation revealed that the wheel loader operator was not working efficiently, causing loading to take an excessive amount of time. By creating a digital twin of the site, we were able to analyse the impact of process changes and concluded that the customer could reduce cost per tonne by 18% with minor changes in their cycle time. Operator training from Volvo was recommended as one of the next steps.

Partnering for a sustainable future

Your competitors will inevitably join this transformation sooner or later, if they haven’t already. Starting early may present challenges, but being late could be devastating for your business. We are eager to assist you in this journey as it aligns with our purpose of making this world a better place to live in.

By collaborating with our customers, we can increase their efficiency and contribute to society’s sustainable development by reducing the carbon footprint and improving resource utilisation – always with people’s health, safety, and well-being at the forefront of our actions. This is why we drive innovation and work closely with our customers to create a world that is cleaner, safer, and more connected, every day.