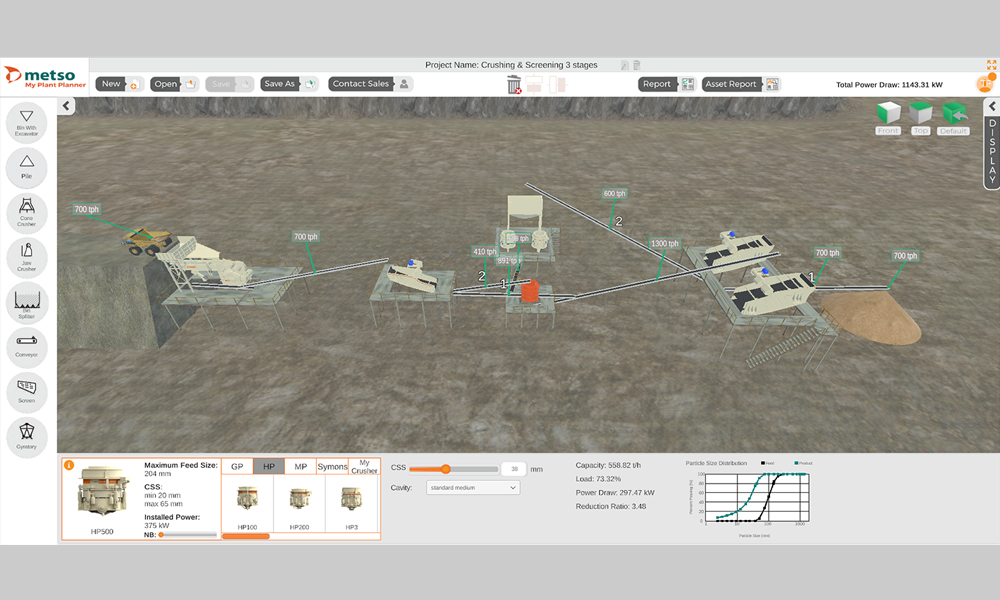

A new free-to-use 3D crushing and screening plant configurator from Metso is enabling the mining and aggregate industries to design more productive and efficient plants through real-time insights.

The Finnish materials processing equipment giant said its new drag-and-drop design and simulation tool, called My Plant Planner, is available on its website metso.com.

According to a statement from Metso, My Plant Planner is based on proprietary Metso software VPSTM and BrunoTM. It has some has unique features and insights to help in the planning of optimised crushing and screening circuits, such as the possibility to design and simulate the ideal crushing and screening circuit in the same tool in 3D. The configurator makes it easy to predict general power consumption of the system and to see the footprint of the circuit, which Metso says is an exclusive feature of the configurator. It is also possible to download a detailed report of the designed plant.

Guillaume Lambert, vice president, Crushing Systems, at Metso, said: “We are really excited about My Plant Planner. Our aim is to help our customers easily test different configurations and operating conditions to see how they affect process performance. The tool allows you to either design and simulate a new crushing and screening plant in 3D or test how upgrading your current equipment can improve performance.”

According to Metso, the tool allows users to pick and choose different types of crushers, screeners and conveyors to get the perfect balance for the circuit and easily identify bottlenecks to understand where extra capacity is needed. Important factors, such as capacity, load, and power draw, are updated in real-time as the circuit is designed and the parameters updated. At any point, it is possible to download a report that gathers together all the details about the plant being designed. It includes details on the chosen crushers, screens, conveyors and their parameters, including power consumption.