Volvo Construction Equipment (Volvo CE) is building a test and demonstration area for electric autonomous transport solutions at its Customer Centre in Eskilstuna, Sweden, which it says is the world’s first of its kind.

The Swedish equipment giant said in a statement that construction has already begun at its Customer Centre on a new area dedicated to testing and demonstrating the latest innovations in sustainable power, connectivity and autonomous solutions. The new area is expected to open by autumn 2021 at the latest, said the company.

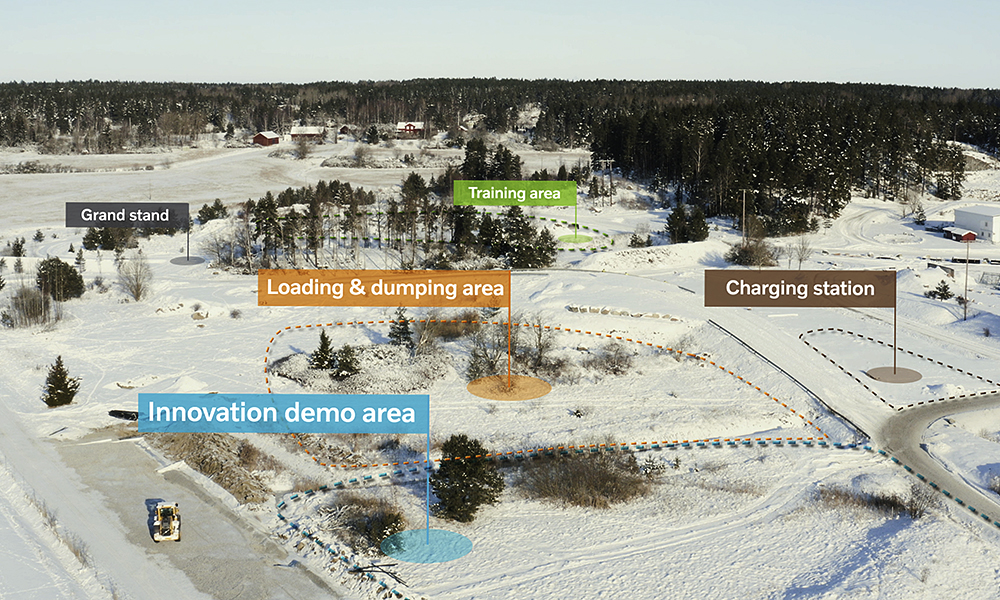

This 66,000sqm zone will include a secure track for full-electric, automated and teleoperated machines with charging infrastructures and 5G connectivity, a control and training room building, a spectator stand and training area for the Volvo Co-Pilot assist functions.

The display at the zone will be headlined by the TARA autonomous transport solution from Volvo Autonomous Solutions for defined sites, such as quarries or mines.

Calle Skillsater, technical specialist in connected machines at Volvo Autonomous Solutions, said: “We are excited to demonstrate our complete TARA solution to customers, including how to set up and run the site, how to charge and store the TA15 electric autonomous haulers, and how we manage the control room and surveillance operations – everything in a brand-new state-of-the-art facility.”

Using two teleoperation rigs installed in one of the control rooms, the secure track will also showcase remote-controlled machines, which are also ideal for working in quarries or mines. Another of the control rooms will offer real-time demonstrations of how the company’s uptime and productivity services can reduce customers’ total cost of ownership and operation.

Carl Slotte, head of Sales Region Europe & International, at Volvo CE, said: “This is an important strategic investment, not just for Volvo CE and Volvo Autonomous Solutions but the entire Volvo Group – and is proof of our commitment to drive sustainability through innovation. We are looking forward to welcoming visitors to this world-class facility and allowing them to experience exactly how we are building tomorrow.”