Hyundai Doosan Infracore has celebrated the production of its 500,000th environmentally friendly small-sized G2 engine with a ceremonial event at its Incheon G2 factory, in South Korea.

The production and shipping of its 500,000th 1.8 to 3.4L grade small-sized G2 engine, comes as the plant completes ten years in business following its first production in October 2012 when the G2 engine plant wasbuilt.

The ceremony was attended by more than 70 employees including Hyundai Doosan Infracore CEO and President Cho Young-cheul, CEO and Vice President Oh Seung-hyun, Engine Business Head Kim Joong-soo, and Labor Union Head Yoo Joon-mo.

“The G2 engine is a high-efficiency, environmentally friendly engine produced with our very own technology and will be a key player that competes with global engine makers in markets such as the United States and Europe,” said CEO Cho Young-cheul at the ceremony.

Speaking about the future vision for G2 engines he added, “We need to create a systematic production system in order to reach total production of one million engines in the next five years, which will require twice the current speed. Please also work on creating synergy between our three construction equipment companies as these engines will be applied to Hyundai Genuine’s forklifts and other vehicles along with Hyundai Doosan Infracore and Hyundai Construction Equipment’s excavators developed on a new integrated platform.”

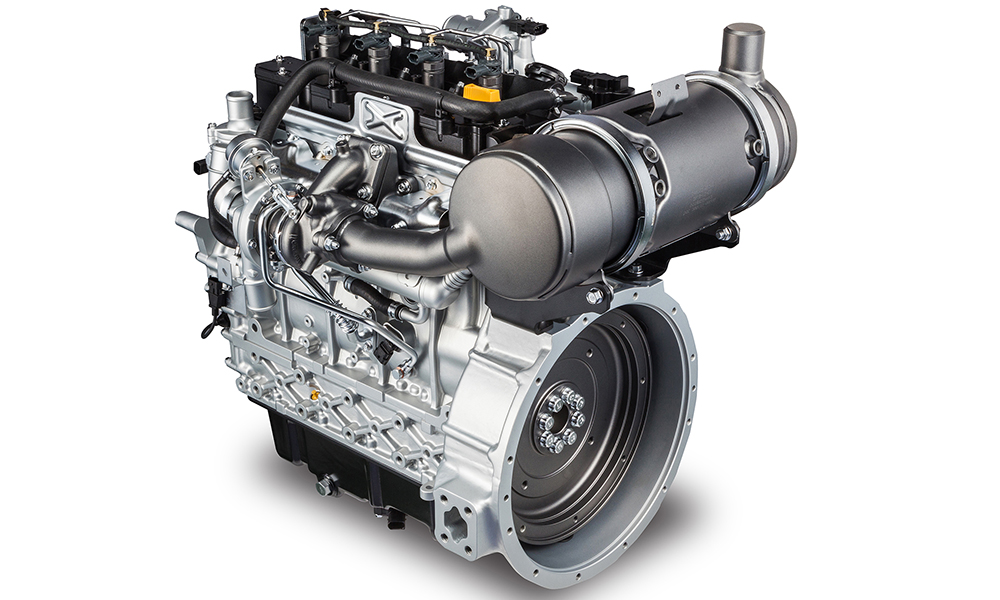

Hyundai Doosan Infracore’s G2 engine is an eco-friendly and highly efficient model that satisfies EU Stage V, the highest emission regulation in Europe and is used in various types of construction equipment along with forklifts and agricultural machines.

The company says it plans to increase yearly capacity which is currently at 70,000 engines to 100,000 engines going forward by creating and expanding new productions externally.